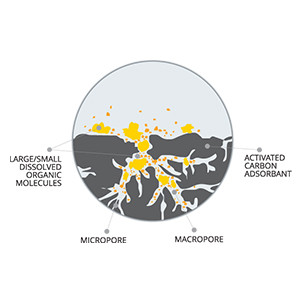

Activated Carbons are the most powerful adsorbents known. It is basically a solid material consisting mainly of pure carbon.When the carbon is activated it leads to opening of various pores in its structure. A characteristic feature is its porous structure and the resulting immense surface area which may be as large as 1000m2/gm.

Activated Carbons are the most powerful adsorbents known. It is basically a solid material consisting mainly of pure carbon.When the carbon is activated it leads to opening of various pores in its structure. A characteristic feature is its porous structure and the resulting immense surface area which may be as large as 1000m2/gm.

Due to its exceptional adsorption qualities, activated carbon is widely used in process destined to purify, discolor, recuperate and remove odors at low cost and superior efficiency.

Activated carbons work on the principle of adorption. Adsorption is an interfacial process involving the collection of gaseous or solute components on the surface of adsorbent solids.

Applications of Activated Carbon:

- Effluent Treatment Plant to reduce BOD/COD/Colour from Industrial waste water.

- Purification of drinking water. Air & Gas mask.

- To absorb moisture from compressed Air for paint shop.

- To De-chiorinate soft drink plant process water & swimming pools.

- To remove oil from hot condensate.

- To remove oil vapour from Gas Stream.

- Solvent recovery & Gold recovery.

- Removal of dissolved organic impurities.

- To remove odor.

- Breweries & distilleries.

- Catalyst carrier in Petroleum Refineries.

- Purification of carbon dioxide & Industrial Gas.

Decolourisation

Used in Pharmaceutical Formulation, IV Fluid & Laboratory Chemicals, Pesticides & Insecticides Industries.

- Textile

- Dyes and dye Intermediates

- Organic and Inorganic Chemicals

- Agrochemicals

- Sugar manufacturers

Starch and Glucose manufacturers

Manufacturing Process

There are two types of processing process.

- Steam Activation.

- Chemical Activation.

We manufacture Steam Activated Carbon which is commonly used across the world.